Applications of Sensors in Cranes

Sensors play a crucial role in modern cranes, enhancing their functionality, safety, and efficiency. These devices are integral to the operation of cranes, enabling precise control, monitoring, and automation. This article explores the various applications of sensors in cranes and their significance in improving operational performance.

Displacement Sensors

Displacement sensors are used to measure the position and movement of crane components, such as the hook, boom, or counterweight. These sensors provide real-time data on the crane's positioning, ensuring accurate lifting and placement of loads. They are critical for maintaining stability and preventing overloading.Force Sensors

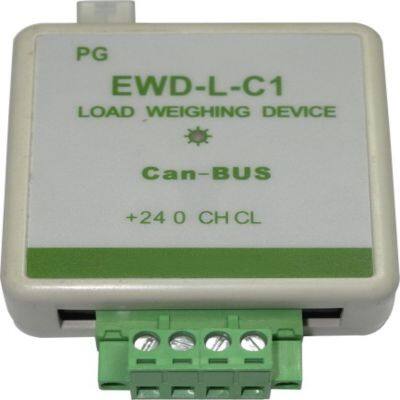

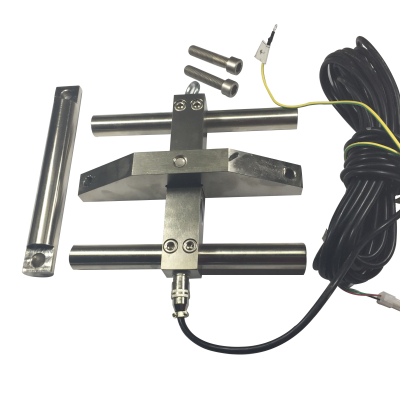

Force sensors, also known as load cells, measure the weight of the load being lifted. This information is essential for ensuring that the crane operates within its specified load capacity. Overloading can lead to equipment failure or accidents, making force sensors a vital component of crane safety systems.Angle Sensors

Angle sensors are used to monitor the angle of the crane's boom or jib. By tracking the angle, these sensors help prevent the crane from exceeding safe operating limits, reducing the risk of tipping or structural failure. They are particularly important in tower cranes and construction cranes.

Proximity Sensors

Proximity sensors detect the presence of objects near the crane's moving parts. These sensors are used to prevent collisions between the crane and surrounding structures or personnel. They also ensure safe operation by signaling when the crane is too close to obstructions.Tilt Sensors

Tilt sensors monitor the crane's stability by measuring the angle of the mast or chassis. These sensors are critical for preventing overturning, especially in mobile cranes or tower cranes operating on uneven ground. They provide early warnings if the crane is at risk of tipping over.Temperature and Vibration Sensors

Temperature and vibration sensors monitor the condition of the crane's mechanical components. These sensors detect unusual heat or vibrations, which may indicate wear and tear or potential failures. They help in predictive maintenance, reducing downtime and extending the crane's operational life.

GPS and Wireless Sensors

In some advanced cranes, GPS and wireless sensors are used for precise location tracking and data trang and data transmission. These sensors enable remote monitoring and control, allowing operators to manage crane operations from a safe distance, especially in hazardous environments.

Load Monitoring

Sensors are used to monitor the weight and distribution of the load being lifted. This ensures that the crane operates safely within its load limits and prevents overloading.Boom Angle Control

By measuring the angle of the boom, sensors help maintain the crane's stability and prevent it from exceeding its operational limits. This is particularly important in high-reach cranes where the boom angle directly affects the crane's center of gravity.

Collision Avoidance

Proximity sensors and radar systems are integrated into cranes to detect obstacles in the vicinity. These systems provide alerts or automatically stop the crane's movement to prevent collisions.Operator Assistance Systems

Sensors provide real-time data to the operator, helping them make informed decisions. For example, load weight, boom angle, and tilt data are displayed on a control panel, enabling safer and more efficient operations.Automation and Remote Control

Advanced cranes use sensors for automation, allowing operators to control the crane remotely. This is especially useful in hazardous environments or in situations where manual operation is challenging.Predictive Maintenance

By monitoring temperature, vibration, and other parameters, sensors help predict potential failures before they occur. This reduces downtime and extends the crane's operational life.

Enhanced Safety: Sensors help prevent accidents by monitoring load limits, boom angles, and crane stability.

Improved Efficiency: Real-time data enables operators to make quick decisions, optimizing crane performance.

Reduced Downtime: Predictive maintenance ensures that cranes are in optimal working condition, minimizing unexpected breakdowns.

Increased Precision: Sensors provide accurate measurements, ensuring precise lifting and placement of loads.

Cost Savings: By reducing the risk of equipment failure and optimizing operations, sensors help lower operational costs.

The integration of advanced sensors, such as IoT-enabled sensors and AI-driven systems, is expected to further revolutionize crane operations. These technologies will enable smarter, more efficient, and safer crane systems, capable of adapting to changing conditions in real time.

ConclusionSensors are indispensable in modern cranes, playing a pivotal role in enhancing safety, efficiency, and performance. As technology continues to advance, the application of sensors in cranes will become even more sophisticated, driving innovation in the construction, manufacturing, and transportation industries. By leveraging the power of sensors, crane operators can ensure safer, more reliable, and cost-effective operations.

website:https://elevatorest.com/

WhatsApp: +86 18092239472

Email:fmssales3@xafms.com

Recently Posted

-

Why Elevator Weight Measurement Equipment Is Essential for Modern Buildings

October 17, 2025Elevators are an essential part of modern buildings, providing efficient vertical transportation in residential, commercial, and i Read More

Read More -

Elevator Load Sensors: Choosing the Perfect Fit for Your System

October 15, 2025How to Choose the Right Load Sensors for Elevators: A Comprehensive GuideElevator load sensors are critical components that ensure Read More

Read More -

Top Tips for Finding the Most Cost-Effective Elevator Weight Measurement Systems

October 11, 2025How to Find the Most Cost-Effective Elevator Weight Measurement SystemsWhen it comes to selecting elevator weight measurement syst Read More

Read More -

Enhance Elevator Safety: A Comprehensive Guide to Choosing Weight Measurement Equipment

October 10, 2025How to Choose the Right Elevator Weight Measurement EquipmentElevators are essential components of modern buildings, and ensuring Read More

Read More