Elevator Load Sensors: Choosing the Perfect Fit for Your System

How to Choose the Right Load Sensors for Elevators: A Comprehensive Guide

Elevator load sensors are critical components that ensure the safe and efficient operation of elevators by measuring the weight of the elevator cab and its contents. Selecting the appropriate load sensor for your elevator system is essential to maintain performance, safety, and compliance with industry standards. In this article, we will explore the key considerations for choosing the right elevator load sensor and discuss the characteristics of two common types: in-cab load sensing and rope head load sensing.

Understanding Elevator Load Sensors

Elevator load sensors are designed to measure the weight of the elevator cab, passengers, and cargo. These sensors provide real-time data to the elevator control system, enabling it to adjust performance, prevent overload, and ensure smooth operation. Choosing the right load sensor depends on the specific requirements of your elevator system, including its capacity, speed, and the type of installation.

Types of Elevator Load Sensors

There are two primary types of load sensors used in elevators: in-cab load sensing and rope head load sensing. Each has unique characteristics and is suited to different applications.

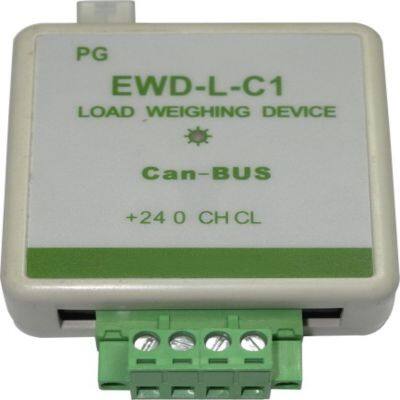

1. In-Cab Load Sensing

In-cab load sensing systems are installed directly on the floor of the elevator cab. These sensors measure the weight of the cab and its contents by detecting the force exerted on the floor. Key features of in-cab load sensors include:

Direct Measurement: Provides accurate and immediate weight readings by measuring the force applied to the cab floor.

Installation Flexibility: Can be easily integrated into the cab structure, making them suitable for a wide range of elevator designs.

Real-Time Monitoring: Offers continuous weight monitoring, which is essential for maintaining safety and preventing overloading.

Space Efficiency: Compact design allows for easy installation without requiring additional space outside the cab.

In-cab load sensors are ideal for elevators that require precise weight measurement and are commonly used in high-speed or high-capacity elevator systems.

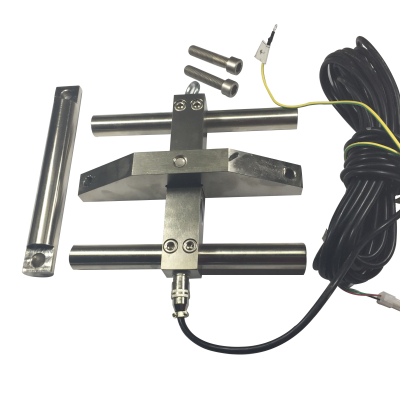

2. Rope Head Load Sensing

Rope head load sensing systems measure the tension in the elevator cables to determine the weight of the cab and its contents. These sensensors are typically installed at the rope head assembly, which connects the elevator cab to the hoistway. Key features of rope head load sensors include:

Indirect Measurement: Uses the tension in the elevator cables to calculate weight, providing an accurate representation of the cab's load.

Durability: Designed to withstand the stress and strain of elevator operations, making them ideal for long-term use.

Minimal Maintenance: Requires less frequent calibration compared to in-cab sensors, reducing maintenance costs.

Wide Compatibility: Suitable for a variety of elevator types, including older systems that may not have dedicated load sensing infrastructure.

Rope head load sensors are often preferred for their simplicity and reliability, making them a cost-effective solution for many elevator applications.

How to Choose the Right Load Sensor for Your Elevator

Selecting the appropriate load sensor for your elevator system involves considering several factors, including:

Elevator Capacity: Determine the maximum weight your elevator is designed to carry. Choose a load sensor with a capacity that matches or exceeds this limit.

Elevator Speed and Type: High-speed or heavy-duty elevators may require more advanced load sensors to handle their specific operational demands.

Installation Constraints: Consider the physical space available for sensor installation. In-cab sensors are ideal for systems with access to the cab floor, while rope head sensors are better suited for installations where space is limited.

Budget and Maintenance Requirements: Compare the costs of installation, maintenance, and calibration for different sensor types to find the most cost-effective solution.

By evaluating these factors, you can select a load sensor that optimizes performance, safety, and efficiency for your elevator system.

Conclusion

Elevator load sensors are indispensable for ensuring the safe and reliable operation of elevator systems. Whether you choose in-cab load sensing or rope head load sensing, selecting the right sensor depends on your specific needs and the characteristics of your elevator system. By understanding the differences between these two types and considering key factors like capacity, speed, and installation constraints, you can make an informed decision that enhances the performance of your elevator system.

Recently Posted

-

Why Elevator Weight Measurement Equipment Is Essential for Modern Buildings

October 17, 2025Elevators are an essential part of modern buildings, providing efficient vertical transportation in residential, commercial, and i Read More

Read More -

Top Tips for Finding the Most Cost-Effective Elevator Weight Measurement Systems

October 11, 2025How to Find the Most Cost-Effective Elevator Weight Measurement SystemsWhen it comes to selecting elevator weight measurement syst Read More

Read More -

Enhance Elevator Safety: A Comprehensive Guide to Choosing Weight Measurement Equipment

October 10, 2025How to Choose the Right Elevator Weight Measurement EquipmentElevators are essential components of modern buildings, and ensuring Read More

Read More -

Electronic Instrument Sensors: Empowering Industries with Precision and Reliability

September 26, 2025In the modern era, electronic instrument sensors have become the backbone of innovation, enabling industries to operate more effic Read More

Read More