Enhance Elevator Safety: A Comprehensive Guide to Choosing Weight Measurement Equipment

How to Choose the Right Elevator Weight Measurement Equipment

Elevators are essential components of modern buildings, and ensuring their safe and efficient operation is crucial. Elevator weight measurement equipment plays a vital role in maintaining the performance and longevity of these systems. Whether you're installing a new elevator or upgrading an existing one, selecting the right weight measurement equipment is a critical decision. This guide will walk you through the key factors to consider when choosing elevator weight measurement equipment.

1. Understand the Purpose and Requirements

The first step in selecting elevator weight measurement equipment is understanding its intended use. Elevators in residential buildings, commercial complexes, hospitals, or industrial settings have different operational requirements. Determine the maximum weight capacity your elevator will need to handle, as this will directly influence the type of equipment you need.

2. Accuracy and Reliability

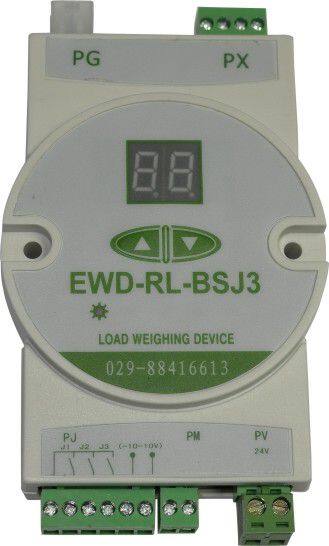

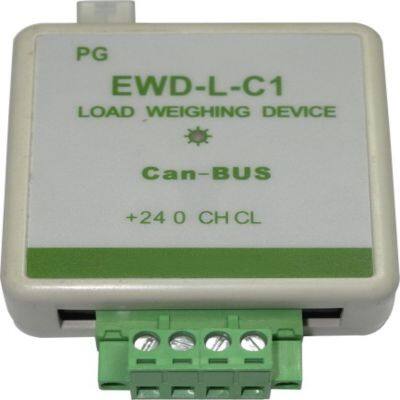

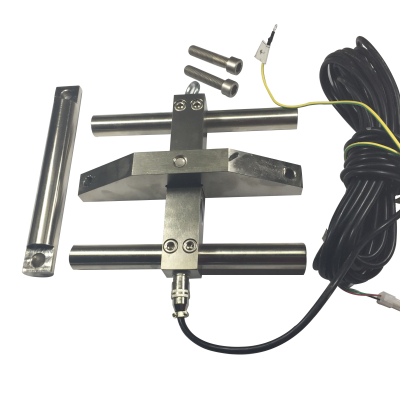

Accurate weight measurement is essential for the safe and efficient operation of elevators. Look for equipment that offers high precision and reliability. Advanced systems often use load cellls or strain gauges to measure weight accurately. Ensure the equipment can provide real-time data and has a low margin of error.

3. Installation and Compatibility

The equipment must be compatible with the elevator's design and structure. Consider the space available for installation, as well as the compatibility with existing elevator controls and systems. Some systems may require additional modifications, so it's important to consult with manufacturers or experts to ensure seamless integration.

4. Regulatory Compliance

Elevator weight measurement equipment must comply with local and international safety standards. Check for certifications such as ISO, CE, or other relevant standards to ensure the equipment meets the necessary regulations. Compliance is not only a legal requirement but also a guarantee of quality and safety.

5. Budget and Long-Term Costs

While cost is a key factor, it's important not to compromise on quality. Compare the upfront costs with the long-term benefits, such as durability, maintenance requirements, and potential savings from energy efficiency. Some systems may have higher initial costs but offer better performance and lower maintenance expenses over time.

6. Brand and Support

Choosing a reputable brand is essential for reliable performance and after-sales support. Look for manufacturers with a proven track record in elevator technology and customer service. Ensure they offer technical support, warranties, and spare parts availability.

7. Testing and Validation

Before finalizing your choice, test the equipment under real-world conditions. Validate its performance, accuracy, and reliability in your specific environment. This step ensures that the equipment meets your operational needs and expectations.

Conclusion

Selecting the right elevator weight measurement equipment is a decision that impacts safety, efficiency, and operational costs. By considering factors such as accuracy, compatibility, regulatory compliance, and brand reputation, you can choose a system that meets your needs and provides long-term value.

Recently Posted

-

Why Elevator Weight Measurement Equipment Is Essential for Modern Buildings

October 17, 2025Elevators are an essential part of modern buildings, providing efficient vertical transportation in residential, commercial, and i Read More

Read More -

Elevator Load Sensors: Choosing the Perfect Fit for Your System

October 15, 2025How to Choose the Right Load Sensors for Elevators: A Comprehensive GuideElevator load sensors are critical components that ensure Read More

Read More -

Top Tips for Finding the Most Cost-Effective Elevator Weight Measurement Systems

October 11, 2025How to Find the Most Cost-Effective Elevator Weight Measurement SystemsWhen it comes to selecting elevator weight measurement syst Read More

Read More -

Electronic Instrument Sensors: Empowering Industries with Precision and Reliability

September 26, 2025In the modern era, electronic instrument sensors have become the backbone of innovation, enabling industries to operate more effic Read More

Read More