Home > Blog > How to Pair Elevator Weight Measurement Controllers and Sensors for Optimal Performance

-

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How to Pair Elevator Weight Measurement Controllers and Sensors for Optimal Performance

2025-08-15 17:02:51

Elevator systems are critical components of modern buildings, ensuring the safe and efficient transportation of passengers and goods. Among the essential subsystems in elevators, weight measurement plays a vital role in ensuring operational safety, load distribution, and energy efficiency. The integration of a controller and sensor system for elevator weight measurement is a complex task that requires careful consideration of compatibility, accuracy, and reliability. This article explores how to pair elevator weight measurement controllers and sensors effectively to achieve optimal performance.

Understanding the Components: Controllers and Sensors

Before diving into the pairing process, it is essential to understand the roles of controllers and sensors in an elevator weight measurement system.

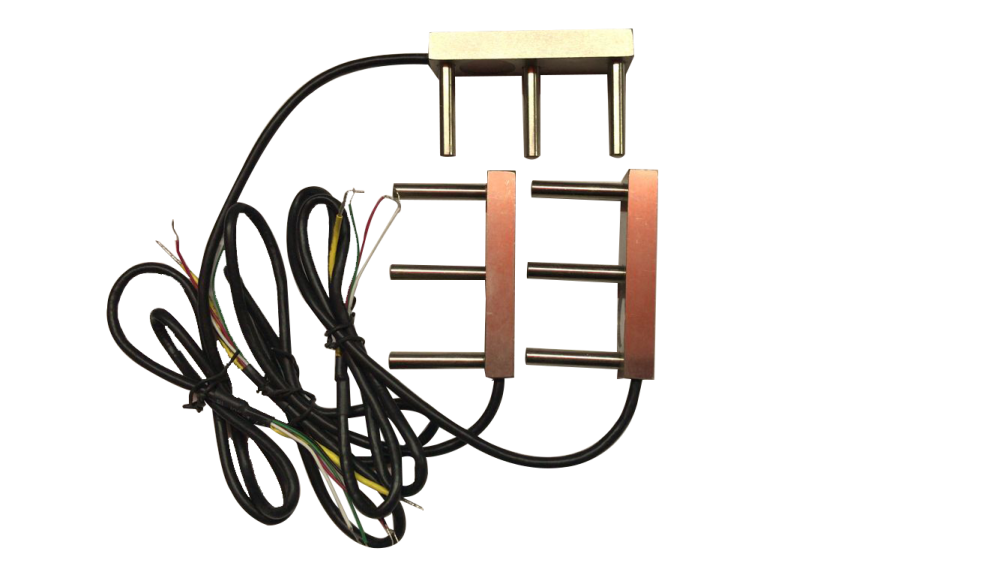

Sensors: These devices are responsible for detecting the weight applied to the elevator car or its load. Common types of sensors used in elevators include strain gauges, load cells, and pressure sensors. Each type has its own characteristics, such as sensitivity, response time, and accuracy.

Controllers: Controllers process the data received from the sensors and use it to make decisions or adjustments. They can be simple analog devices or advanced microcontrollers with embedded algorithms. Controllers are responsible for interpreting sensor data, performing calculations, and sending commands to other subsystems (e.g., motor control, safety mechanisms).

Key Considerations for Pairing Controllers and Sensors

Compatibility of Signal Types

The most critical factor in pairing controllers and sensors is ensuring compatibility in terms of signal types. For example, if a sensor outputs an analog signal (e.g., voltage or current), the controller must have the capability to accept and process such signals.

Digital sensors, which output discrete binary data, require controllers with digital input capabilities. Compatibility ensures seamless communication and accurate data transfer between the two components.

Precision and Accuracy

The accuracy of the sensor and the controller's ability to process its data directly impact the overall system's reliability. High-precision sensors are essential for applications where load accuracy is critical, such as in freight elevators or elevators with strict weight limits.

The controller should have sufficient processing power to handle the sensor's resolution and minimize errors in calculations.

Response Time

Elevator systems require real-time data processing to ensure smooth operation and safety. Sensors with fast response times must be paired with controllers capable of processing data quickly.

Delays in signal processing can lead to inefficient load distribution or safety issues, such as overloading.

Integration Capabilities

Modern elevator systems often rely on integrated control systems. The controller should be able to integrate with other subsystems, such as motor control units, safety systems, and monitoring sof and monitoring software.

Sensors must be designed to work within the broader system architecture, ensuring seamless integration and communication.

Environmental Factors

Elevator environments can be harsh, with vibrations, temperature fluctuations, and electromagnetic interference (EMI). Both sensors and controllers must be rated for the specific environmental conditions they will operate in.

Sensors with EMI shielding and controllers with robust signal processing algorithms are preferable in such environments.

Scalability and Future-Proofing

As elevator systems evolve, the controller and sensor pairing should allow for scalability. This means the system should be capable of handling future upgrades or additional features, such as advanced load management algorithms or connectivity to building management systems.

Steps to Optimize Pairing

Define System Requirements

Begin by defining the specific requirements of the elevator system, such as maximum load capacity, desired accuracy, response time, and environmental constraints. This will guide the selection of both the sensor and controller.

Select the Sensor

Choose a sensor that meets the system's accuracy, response time, and environmental requirements. Consider factors like the sensor's load range, tolerance, and output signal type (analog or digital).

Choose the Controller

Select a controller that is compatible with the sensor's output signal and has sufficient processing power. Controllers with built-in algorithms for load calculations, safety checks, and communication protocols are ideal.

Ensure Signal Conditioning

If the sensor and controller are not directly compatible, consider adding signal conditioning hardware or software. For example, an analog-to-digital converter (ADC) can bridge the gap between an analog sensor and a digital controller.

Test and Calibrate

Before finalizing the pairing, perform extensive testing to ensure accurate data transmission and processing. Calibration is critical to ensure that the system provides reliable and precise weight measurements.

Implement Redundancy and Safety Features

To enhance reliability, implement redundancy in both the sensor and controller systems. For example, using multiple sensors and cross-checking their readings can improve accuracy and safety.

Real-World Applications and Best Practices

In practical applications, the pairing of controllers and sensors in elevator systems often involves the following best practices:

Use High-Quality Components: Invest in sensors and controllers from reputable manufacturers with proven track records in industrial and elevator applications.

Regular Maintenance: Schedule routine maintenance to ensure the longevity and accuracy of both components.

Software Updates: Keep the controller's firmware up to date to benefit from the latest algorithms and safety features.

Consult Industry Standards: Adhere to industry standards, such as those set by the International Organization for Standardization (ISO), to ensure compliance and safety.

Conclusion

The effective pairing of elevator weight measurement controllers and sensors is essential for ensuring the safety, efficiency, and reliability of elevator systems. By carefully considering compatibility, precision, response time, and environmental factors, engineers can design systems that meet the demands of modern buildings. As technology continues to advance, the integration of advanced sensors and intelligent controllers will play a pivotal role in elevating the performance of elevator systems worldwide.

Tags: Controllers and Sensors, Steps to Optimize Pairing, Implement Redundancy and Safety