-

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Sensors in the Food Industry: Revolutionizing Quality, Safety, and Efficiency

2025-08-09 09:33:51

The food industry is constantly evolving to meet the demands of a growing population, stricter regulatory standards, and the need for sustainable practices. Sensors have become indispensable tools in this sector, enabling precise monitoring, quality control, and real-time data analysis. By integrating sensors into food production, processing, and distribution, companies can ensure safety, optimize resources, and maintain consistent product quality. This article explores the impact of sensors in the food industry and highlights how our innovative products can enhance your operations.

Impact of Sensors in the Food Industry

Temperature and Humidity Monitoring

Temperature and humidity are critical factors in food safety and shelf life. Sensors are used throughout the supply chain to monitor cold storage, refrigeration systems, and packaging conditions. By maintaining optimal temperature ranges, sensors help prevent spoilage, reduce waste, and ensure compliance with food safety regulations.Quality Control and Consistency

Sensors enable real-time monitoring of product quality during processing. For example, sensors can measure parameters such as texture, color, and moisture content, ensuring consistent product quality and reducing defects.Food Safety and Contamination Detection

Advanced sensors can detect contam

inants, such as bacteria, heavy metals, or foreign objects, in raw materials or finished products. This helps prevent foodborne illnesses and ensures compliance with food safety standards.

Process Optimization

Sensors provide valuable data on production processes, such as mixing, cooking, and packaging. This data can be used to optimize workflows, reduce energy consumption, and improve efficiency.Supply Chain Transparency

Sensors embedded in packaging or transportation systems allow for real-time tracking of food products. This ensures that products remain within safe temperature and humidity ranges during transit, reducing the risk of spoilage.Waste Reduction

By monitoring expiration dates, spoilage indicators, and storage conditions, sensors help reduce food waste, which is a significant challenge in the food industry.

Key Features of High-Quality Food Industry Sensors

Precision and Accuracy

Sensors must provide reliable and accurate measurements to ensure the safety and quality of food products.Durability and Hygiene

Sensors designed for the food industry must be resistant to harsh environments, such as high temperatures, moisture, and frequent cleaning.

Real-Time Data

Real-time data transmission allows for immediate action to be taken if any deviations occur, minimizing risks and downtime.Customization

Sensors can be tailored to specific food types, production processes, and rd regulatory requirements, ensuring optimal performance.

Our company offers a range of sensors designed to meet the unique challenges of the food industry:

Temperature and Humidity Sensors

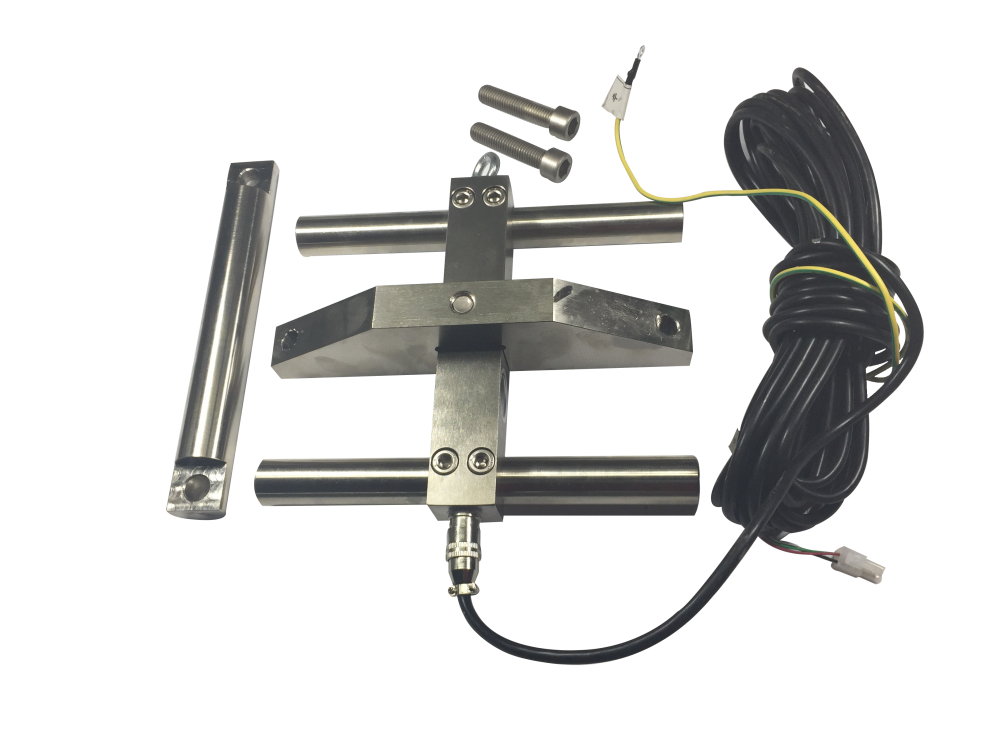

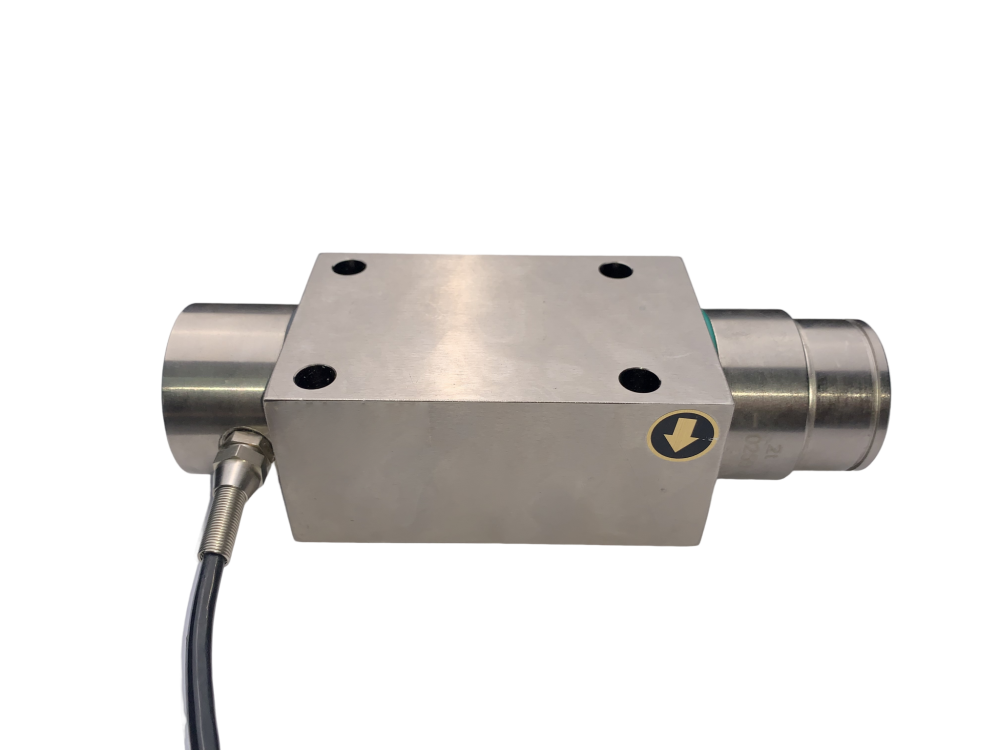

These sensors are ideal for monitoring cold storage, refrigeration systems, and packaging conditions. They provide accurate readings in real time, ensuring food safety and reducing waste.Weight and Pressure Sensors

Used in processing and packaging, these sensors ensure consistent product weight and proper sealing, reducing defects and improving customer satisfaction.

pH and Chemical Sensors

These sensors measure acidity, moisture, and other chemical properties, ensuring product quality and safety during production.Gas Sensors

Detect harmful gases, such as carbon dioxide or ethylene, to monitor food ripening and freshness in storage facilities.Customizable Sensors

Our sensors can be programmed to meet the specific needs of your production process, ensuring seamless integration into your workflow.

Why Choose Our Products?

Performance Stability

Our sensors are built to deliver consistent and reliable performance, even in challenging environments.Fast Reaction Time

Real-time data acquisition and processing enable quick decision-making, minimizing risks and downtime.Customization

We offer flexible customization options to meet the unique requirements of your food production process.

Conclusion

Sensors are transforming the food industry by enhancing quality, safety, and efficiency. From monitoring temperature and humidity to detecting contaminants, sensors provide actionable insights that help businesses thrive in a competitive market. By choosing our sensors, you can ensure that your food products meet the highest standards of quality and safety while optimizing your operations.

Contact us today to learn more about how our sensors can revolutionize your food production process and help you achieve success in the food industry.

website:https://elevatorest.com/

WhatsApp: +86 18092239472

Email:fmssales3@xafms.com

Tags: food industry, Weight and Pressure Sensors, Gas Sensors