-

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Dandelion

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How Weighing Equipment Enhances Elevator Operational Efficiency

2025-08-02 08:56:47

Elevators are a critical component of modern buildings, especially in high-rise structures where they play a vital role in ensuring the smooth movement of passengers and goods. However, optimizing elevator performance to meet the demands of a dynamic environment requires advanced technologies. One such technology that significantly contributes to elevator efficiency is weighing equipment. By integrating weighing systems into elevator operations, building managers and engineers can enhance safety, reduce energy consumption, and improve overall operational efficiency. This article explores how weighing equipment plays a pivotal role in elevating elevator performance.

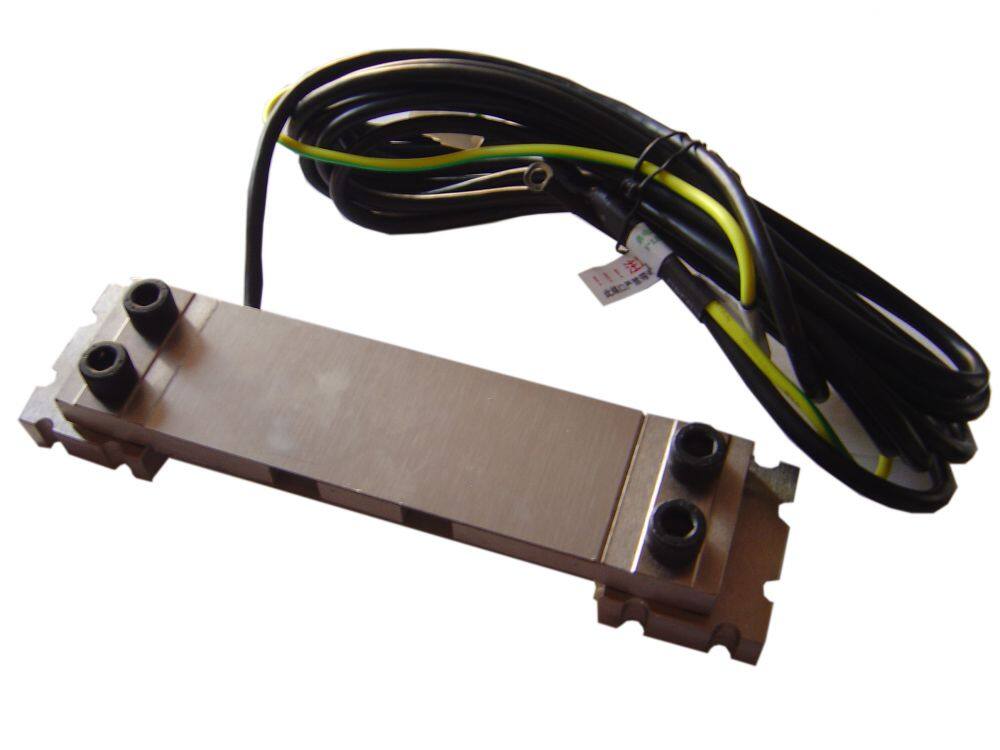

One of the primary functions of weighing equipment in elevators is to monitor the load within the car bottom (cab). Advanced weighing sensors are installed in the elevator floor or suspension system to accurately measure the weight of passengers and cargo. This real-time data allows the elevator system to prevent overload situations, which can be dangerous and damaging to the equipment. By detecting when the load exceeds the maximum capacity, the system can alert passengers or even prevent the elevator from moving until the load is reduced. This not only ensures passenger safety but also extends the lifespan of the elevator machinery.

Weighing equipment enables elevators to operate more efficiently by adjusting their performance based on the load. For instance, if the elevator detects a lighter load, it can optimize energy consumption by reducing power usage during acceleration or deceleration. Conversely, a heavier load may trigger the system to adjust its speed or acceleration parameters to maintain smooth operation. This dynamic adjustment ensures that the elevator operates within safe and efficient parameters, reducing wear and tear and conserving energy.

Energy consumption is a significant concern in modern rn buildings, and elevators are often among the largest consumers of electricity. Weighing equipment helps mitigate this issue by enabling the elevator system to operate more efficiently. For example, when the elevator detects a low load, it can enter an energy-saving mode, reducing power usage during periods of low demand. Additionally, load data can be used to optimize elevator routing, ensuring that the elevator serves multiple stops efficiently without unnecessary stops or idling. These measures collectively contribute to significant energy savings over time.

Beyond operational efficiency, weighing equipment also enhances the passenger experience. By monitoring the load, the elevator system can prioritize stops and optimize the order of requests, reducing wait times and improving responsiveness. In high-traffic buildings, this feature is particularly valuable, as it ensures that the elevator system can handle demand effectively without delays. Additionally, the ability to prevent overloading ensures that passengers can use the elevator with peace of mind, knowing that safety is a top priority.

Weighing equipment also provides valuable data for maintenance and predictive analytics. By tracking load patterns over time, building managers can identify trends and predict potential issues before they occur. For example, if the elevator consistently operates at near-maximum capacity during certain hours, this data can inform decisions about optimizing elevator schedules or upgrading the system to handle higher loads. Predictive maintenance based on load data can also reduce downtime and extend the lifespan of elevator components, ensuring reliable operation.

In the era of smart buildings, weighing equipment can be seamlessly integrated with building management systems (BMS). This integration allows for a holistic approach to elevator management, where load data is used to enhance overall building efficiency. For instance, load information can be used to coordinate elevator movements with energy management systems, ensuring that elevators operate in harmony with other building functions. This level of integration not only improves elevator performance but also contributes to the sustainability and efficiency of the entire building.

Weighing equipment is a powerful tool that enhances elevator operational efficiency in numerous ways. From preventing overloads and optimizing performance to improving energy efficiency and enhancing the passenger experience, the integration of weighing systems into elevators represents a significant advancement in building technology. As buildings continue to evolve, the role of weighing equipment in elevators will only grow more important, ensuring safer, more efficient, and more sustainable vertical transportation solutions for the future. By leveraging this technology, building managers can unlock the full potential of their elevaenvironment for both passengers and the planet.

website:https://elevatorest.com/

WhatsApp: +86 18092239472

Email:fmssales3@xafms.com

Tags: load cell, sensors manufacture, accessories